Thermostat Types MBC 8000 and MBC 8100

MBC 8000 and MBC 8100 thermostats designed for use in severe industrial and marine applications where space and reliability are the most important features.

MBC 8100 have all international marine approvals. The MBC thermostats are designed according to our block design to survive in the harsh conditions known from machine rooms among others. MBC 8000 and MBC 8100 have high vibration

resistance.

• Compact design,

• A high level of enclosure,

• Robust and reliable construction,

• Resistance to shock and vibration,

• Low differential and high repeatability.

CE marked acc. to EN 60 947-1, EN 60 947-4-1,

CE marked acc. to EN 60 947-1, EN 60 947-4-1,

EN 60 947-5-1

China Compulsory Certificate, CCC

Det Norske Veritas, DNV

American Bureau of Shipping, ABS

Lloyds Register of Shipping, LR

Germanischer Lloyd, GL

Bureau Veritas, BV

Registro Italiano Navale, RINA

Nippon Kaiji Kyokai, NKK

Korean Register of Shipping, KR

Russian Maritime Register of Shipping, RMRS

China Classification Society, CCS

| Electrical specifications | |

|---|---|

| Contact load (Alternating current) | 0.5 A, 250 V, AC15 12 W, 125V, DC 13 |

| Switch | SPDT |

| Environmental conditions | |

|---|---|

| Ambient temperature | – 40 – 70 °C |

| Shock resistance: | 50 g/6 ms Acc. to EN 60068-2-27 Free fall acc. to EN 60068-2-32 |

| Vibration resistance | Sin 4 g, 5Hz – 200 Hz acc. to EN 60068-2-6.*) |

| Enclosure | IP65 to EN 60529 Anodized AlMgSi 1, AW-6082 T6 |

If higher vibrations are present in the system/installation, temperature controls with capillary tube or armoured capillary tube are recommended.)

| Mechanical characteristics | |

|---|---|

| Electrical connection | DIN 43650 plug, Pg 9, Pg 11, Pg 13.5 |

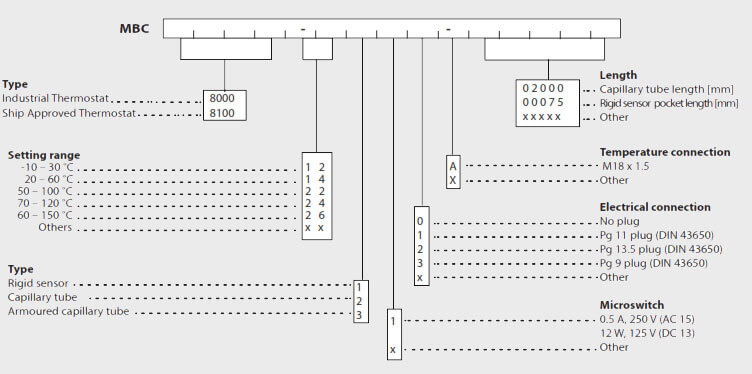

Standard types

Ordering of customized types

Accessories:

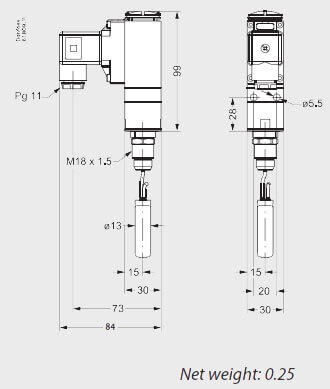

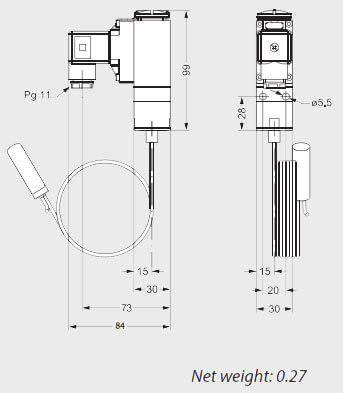

Dimensions [mm] and weights [kg]

Setting point correction

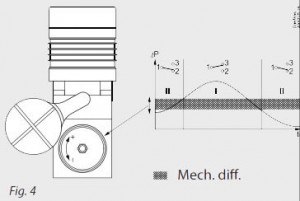

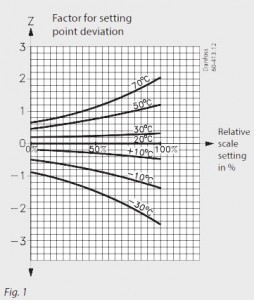

The sensor on MBC 8100 thermostat contains an adsorption charge. Therefore its function is not affected whether the sensor is placed warmer or colder than the remaining part of the thermostatic element (bellows and capillary tube). However, such a charge is to some extent sensitive to changes in the temperature of the bellows and capillary tube. Under normal conditions this is of no importance, but if the thermostat is to be used in extreme ambient temperatures the setting point might change. The deviation can be compensated for as follows: Setting point correction = Z x a Z can be found from fig. 1, while a is the correction factor from the table below.

The sensor on MBC 8100 thermostat contains an adsorption charge. Therefore its function is not affected whether the sensor is placed warmer or colder than the remaining part of the thermostatic element (bellows and capillary tube). However, such a charge is to some extent sensitive to changes in the temperature of the bellows and capillary tube. Under normal conditions this is of no importance, but if the thermostat is to be used in extreme ambient temperatures the setting point might change. The deviation can be compensated for as follows: Setting point correction = Z x a Z can be found from fig. 1, while a is the correction factor from the table below.

Example

A MBC 8100 with capillary tube length 2 m and range 50 – 100 °C must cut out at 75 °C in 70 °C ambient temperature. At which cut out temperature should this temperature control be set at in 20 °C ambient temperature? The relative setting Z can be calculated from the following formula:

Setting value min. range

max. range – min. range

x 100%

Relative setting: 75 – 50

x 100 = 50%

100 – 50

Relative setting:

Factor for setting point deviation Z (fig. 1).

Z – 1.2

Correction factor a (table under fig. 1) a = 2.2

Setting point correction Z x a = 1.2. x 2.2 = 2.6 °C

The MBC must be set at 75 + 2.6 = 77.6 °C in

20 °C ambient temperature in order to cut out

at 75 °C ambient temperature.

Installation

Installation

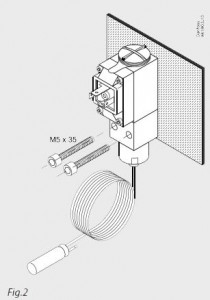

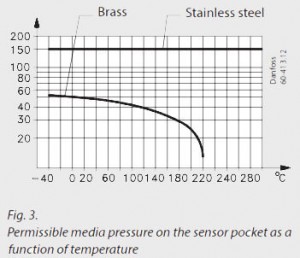

MBC thermostats are designed to withstand theshocks that occur, e.g. in ships, on compressors and in large machine installations. MBC thermostats with remote sensor are fitted with 5mm screws to bulkheads or similar. See fig. 2 MBC thermostats with rigid sensor are self-supporting from the sensor pocket. For permissible media pressure see fig. 3.

Resistance to media

Material specifications for sensor pockets: Sensor pocket, brass The tube is made of CuZn30, CW 505L acc. to EN 12449, the threa ded portion of CuZn39 Pb3, CW 614N acc. to EN 12164. Sensor pocket, stainless steel 18/8Material designation X5CrNi18-10, 1.4301 acc. to EN 10088.

Sensor position

Sensor position

As far as possible the sensor should be positioned so that its longitudinal axis is at

right angles to the direction of flow. The active part of the sensor is ø13 mm x 50 mm long on thermostat with rigid sensors and 2 m capillary tube.

Setting

When the top cover screw at the thermostat is removed, the range can be set with the setting screw. The differential is non-adjustable.